In this post, I’m going to talk about thermal deburring and share my experience as a Technical Manager at SGM Srl, a company that manufactures thermal deburring machines, and at ST Srl, which provides thermal deburring services to a wide range of clients across different sectors.

In precision manufacturing, burrs are more than a nuisanc, they’re failure points waiting to occur. If they are not removed, the small protrusions can disrupt fluid flow, prevent proper sealing, or lead to premature wear. That is why deburring is a required process for different industries including automotive, aerospace, fashion, hydraulics etc.

Among the various deburring methods available, thermal deburring stands out for its unique speed, efficiency, and ability to reach internal burrs that mechanical tools can’t access. Let’s explain how thermal deburring works, where it’s most effective, and etc.

What is Thermal Deburring?

Thermal Energy Method (TEM), commonly known as thermal deburring, is a process that uses a brief but intense burst of combustion to remove burrs from metal parts. The method involves placing one or more components into a sealed chamber filled with a precise mixture of oxygen and fuel gas (commonly methane or hydrogen). Once ignited, the resulting combustion generates an extremely rapid and uniform heat wave—reaching temperatures up to 3000°C in milliseconds.

The complete combustion of methane (CH₄), producing carbon dioxide (CO₂) and water (H₂O).

CH₄ + 2O₂ → CO₂ + 2H₂O

The burrs, due to their high surface area-to-mass ratio, oxidize instantly, while the bulk of the component remains largely unaffected. This makes thermal deburring especially effective for complex internal geometries, small holes, and areas inaccessible by conventional tools.

Generally it is possible to remove burrs and processing scraps having a thickness not exceeding 0.1 mm for zamak, aluminum, copper and their alloys; up to 0.3 mm for ferrous materials.

Here you can read about the process parameters of thermal deburring.

Common application of thermal deburring is as follow:

Hydraulic components (e.g., valve blocks, pump housings)

Automotive parts (e.g., injector nozzles, transmission gears)

Aerospace fittings

Pneumatic systems

Medical implants (selectively, depending on material)

Fashion accessories (e.g., buttons, zippers, perfume caps)

In the fashion industry, it is used to process accessories such as buttons, zippers, perfume caps, and similar components. Instead of manually deburring these small items—which is extremely time-consuming—thermal deburring allows for the rapid treatment of bulk quantities. For example, approximately 5 kg of zippers, which may include up to 10,000 individual pieces, can be deburred in just 40 seconds. This not only saves significant labor time but also ensures uniform quality across all parts.

Advantages of Thermal Deburring

- Uniform Results: Multiple parts can be treated simultaneously with consistent quality.

- Access to Internal Areas: It can remove burrs from complex internal channels and cross-drillings.

- Speed: The process takes only a few milliseconds per cycle.

- No Tool Wear: Unlike mechanical deburring, there are no cutting tools to dull or replace.

Thermal Deburring can also be used as a pre-oxidation process. By oxidizing a very thin surface layer of the material, it helps prevent deeper rust penetration. This can extend the storage life of the part in a warehouse environment.

Challenges & Considerations

Despite its benefits, thermal deburring isn’t a one-size-fits-all solution. Here are a few limitations:

- Material Constraints: Not suitable for plastics, composites, or extremely thin-walled parts.

- Surface Discoloration: Post-processing (e.g., cleaning, passivation) may be needed for aesthetic or functional purposes.

- Safety: Due to the explosive nature of the process, robust safety systems are essential, along with strict compliance with standards such as PED, and, when applicable, ATEX—especially in cases involving robotised conveyors and pick-and-place systems.

- Capital Cost: The machines are complex and require a significant initial investment.

But good news is that according to my experience and data the payback period is about 1 year, which is excellent.

My Experience with Thermal Deburring at SGM

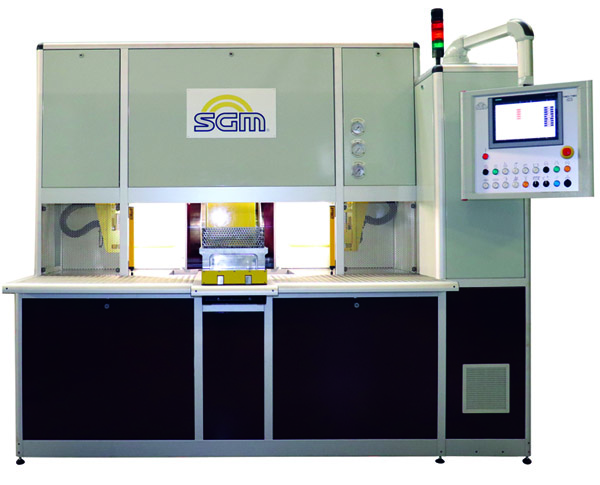

As the Technical Manager at SGM , I’ve had the opportunity to lead the development of advanced thermal deburring machines tailored for international clients with high standards for performance, reliability, and safety. SGM has been a pioneer in this niche, offering machines that combine Italian mechanical excellence with modern automation, safety systems. Our TEM machines are developed with full PED and CE compliance, ensuring operational safety even in demanding environments.

At SGM, we continuously innovate to meet the evolving needs of modern manufacturing. One of our most significant advancements is the SGM NEW-TEM series, which features a vertically oriented combustion chamber—a major leap forward compared to traditional TEM machines.

This design provides several key advantages:

Optimized Space Usage: The vertical design offers a smaller footprint for the same or better productivity, making integration into production lines more flexible and efficient.

Larger Basket Capacity: The vertical layout allows for a bigger basket, meaning more components can be treated per cycle. almost 10 times more than other machines in the market. This not only improves throughput but also reduces handling time and production cost.

Improved Flame Dynamics: In a vertical chamber, the flame travels parallel to the parts rather than directly hitting them. This significantly reduces the risk of surface damage and deformation, even on delicate or precision components.

From semi-automatic loading systems to fully integrated robotic solutions, our machines are built to match customer production lines, cycle time requirements, and space constraints. Whether it’s batch production of small valve bodies or continuous lines for fuel injection systems, we offer modular, scalable solutions that integrate seamlessly with customer needs. Whether it’s batch production of small valve bodies or continuous lines for fuel injection systems, we offer modular, scalable solutions that integrate seamlessly with customer needs.

ST srl- Sbavatura Termica

ST Srl offers thermal deburring services to clients across a wide range of industries. As both ST and SGM are part of the same group, this creates a unique opportunity for continuous exchange of expertise. This close collaboration allows us to adapt and optimize both the thermal deburring machines and the process itself for various sector-specific needs. Notably, SGM is the only manufacturer of thermal deburring machines that works hand-in-hand with a service provider on a daily basis to advance and refine its technology. Sharing the same space, SGM and ST benefit from a direct and dynamic workflow, driving innovation through constant feedback and cooperation.

Conclusion

Thermal deburring remains one of the most efficient and precise methods for removing burrs—especially in components with complex geometries and internal features. Having personally contributed to the design and development of these systems at SGM, I can say with confidence that the future of thermal deburring is smarter, safer, and more productive than ever.

At SGM, we serve clients from all over the world, and many are impressed by our technology. Our goal is to expand these technologies across different continents, and we are actively seeking collaborators globally.

Interested in thermal deburring machines or engineering consulting?

Get in touch via my email or LinkedIn.

Let’s discuss how we can bring next-level precision and safety to your production.

Pingback: Thermal deburring process parameters

Pingback: Red Iron Oxide and Black Iron Oxide - Behrad Mostafaee

Pingback: Surface Treatment: Types, Methods, and Applications - Behrad Mostafaee

Pingback: Extracting dimension of a STEP file using phytone - Behrad Mostafaee

Pingback: Extracting dimension of a STEP file using phyton - Behrad Mostafaee