In this post I’m gonna compare SolidWorks simulation vs ANSYS.

SolidWorks Simulation and ANSYS are engineering simulation and analysis software programs that are used finite element analysis (FEA) and computational fluid dynamics (CFD). They have some commonalities but also have significant distinctions. Here’s a side-by-side comparison:

Integration with CAD:

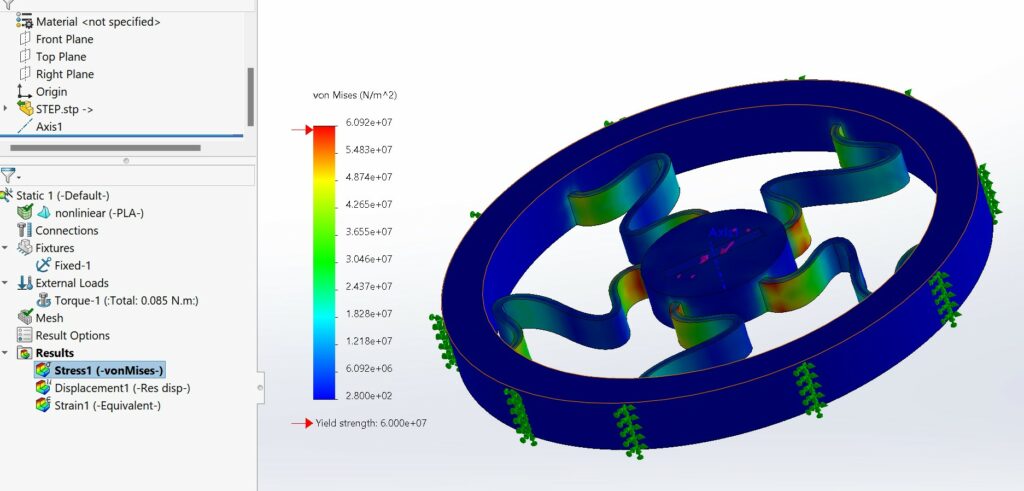

Because SolidWorks Simulation is strongly connected with the CAD program, users may easily move their CAD models straight into the simulation environment. This connection simplifies the design validation procedure.

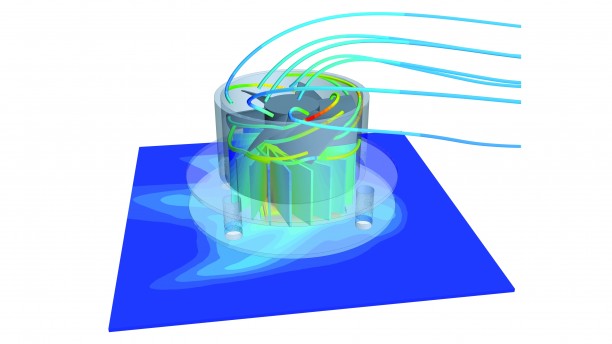

On the other hand, ANSYS can operate with a wide range of CAD applications, providing greater CAD interoperability. It is not restricted to a single CAD system.

User Interface (UI):

SolidWorks Simulation offers a user-friendly interface that is reasonably simple to understand, especially for people who are already familiar with SolidWorks CAD environment.

ANSYS offers a more complicated and broad interface that may be more difficult for beginners to master. It does, however, provide more complex options and customization.

Types of Analyses:

SolidWorks Simulation is well-known for its simplicity in doing fundamental structural and thermal simulations. It is appropriate for a wide range of engineering applications, however it may lack the sophisticated analytical capabilities of ANSYS.

ANSYS is a complete simulation platform that provides a larger range of analysis types, including complex multiphysics simulations such as electromagnetics and fluid dynamics. It is more appropriate for complicated and specialized simulations.

Solver Efficiency:

SolidWorks Simulation, is limited in processing highly big or complicated simulations. It is better suited for small to medium-sized simulations.

ANSYS is well-known for its high-performance solvers, which can successfully handle large and complicated simulations. It is frequently utilized in sectors where precision and accuracy are crucial.

Advanced Functions:

SolidWorks Simulation is designed for simplicity of use and may lack some sophisticated features offered by ANSYS, particularly in specialist areas such as fluid dynamics, electromagnetics, and nonlinear analysis.

ANSYS is a popular choice for complicated simulations since it offers a wide range of sophisticated capabilities and specialized modules for a variety of industries and applications.

Cost:

SolidWorks Simulation is often less expensive for smaller enterprises or individuals that want basic simulation capabilities.

ANSYS can be substantially more expensive, especially when the whole suite of specialist modules is considered. Larger firms with more comprehensive simulation needs frequently employ it.

Community and Help:

SolidWorks offers a large user community with a multitude of tutorials and support resources.

ANSYS offers a big user community as well as significant support tools including as forums, documentation, and training.

In conclusion, the decision between ANSYS and SolidWorks Simulation will depend on your unique simulation requirements, financial constraints, and level of software experience. While ANSYS is better suited for complicated and specialized simulations but is more expensive and may have a steeper learning curve, SolidWorks Simulation is ideal for simpler simulations and offers ease of use.