The Complete Guide to Surface Treatment: Types, Methods, and Applications

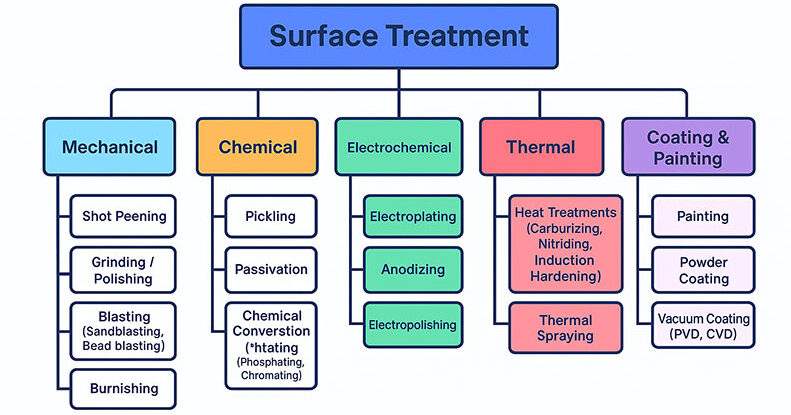

Surface treatment is a critical aspect of materials engineering and manufacturing. It involves various processes applied to the surface of a material to enhance its appearance, performance, corrosion resistance, wear resistance, and other properties. These processes are used across multiple industries, from aerospace and automotive to medical devices and consumer goods.

Before any surface treatment is applied, components sometimes undergo a pre-treatment process such as as thermal deburring.

In this blog post, we will explore the main categories of surface treatment, the most common methods within each category, and the purpose behind each technique [1][2].

1. Mechanical Surface Treatments

Mechanical surface treatments involve the physical alteration of a surface through abrasion, deformation, or other mechanical means.

1.1 Shot Peening

Shot peening is a cold working process where small spherical media (shots) are blasted at a component’s surface. This induces compressive residual stress layers, which significantly enhance fatigue strength and resistance to stress corrosion cracking. It is widely used in the aerospace and automotive industries [3].

1.2 Grinding / Polishing

Grinding uses abrasives to remove surface material and improve dimensional accuracy. Polishing follows, using finer abrasives to enhance the surface finish and aesthetics. These processes are common in precision engineering and decorative components [4].

1.3 Blasting (Sandblasting, Bead Blasting)

Blasting involves projecting abrasive materials (like sand or glass beads) onto a surface to clean, roughen, or prepare it for coating. Sandblasting is aggressive and good for removing rust or old paint, while bead blasting is milder and produces a satin finish [5].

1.4 Burnishing

Burnishing is a finishing process that uses a hard tool to plastically deform the surface without removing material. This increases surface hardness and creates a very smooth, shiny finish. It’s ideal for enhancing aesthetics and wear resistance [6].

2. Chemical Surface Treatments

Chemical surface treatments use chemical solutions to modify or clean the material’s surface, often improving corrosion resistance and paint adhesion.

2.1 Pickling

Pickling involves using acidic solutions to remove oxides, scales, and other contaminants from metal surfaces, especially after welding or heat treatment. It is commonly used for stainless steels and carbon steels to prepare them for further processing [7].

2.2 Passivation

Passivation is a process that removes free iron from stainless steel surfaces using nitric or citric acid, enhancing its corrosion resistance by promoting the formation of a stable oxide layer. It’s critical in the food, medical, and chemical industries [8].

2.3 Chemical Conversion Coating (Phosphating, Chromating)

These processes chemically modify the metal surface to create a corrosion-resistant layer that also serves as a good base for paint or powder coatings. Phosphating is common in automotive applications, while chromating is often used for aluminum in aerospace [9].

3. Electrochemical Surface Treatments

Electrochemical treatments use electrical current and chemical solutions to deposit, remove, or modify surface layers.

3.1 Electroplating

Electroplating involves depositing a thin layer of metal (e.g., nickel, chrome, zinc) onto a conductive surface using an electric current. This enhances corrosion resistance, wear resistance, and appearance. It’s widely used in decorative and protective applications [10].

3.2 Anodizing

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on metal surfaces, especially aluminum. The result is a hard, corrosion-resistant layer that can also be dyed various colors. It’s common in electronics and consumer products [11].

3.3 Electropolishing

This process is the reverse of electroplating—it removes material from a metallic surface using an electrolytic bath. Electropolishing smooths and brightens the surface, improves corrosion resistance, and is widely used in pharmaceutical and food processing equipment [12].

4. Thermal Surface Treatments

Thermal treatments alter the surface’s microstructure by applying heat, either directly or through a medium, to enhance hardness, wear resistance, or other mechanical properties.

4.1 Heat Treatments (Carburizing, Nitriding, Induction Hardening)

- Carburizing: Adds carbon to the surface of low-carbon steel to improve hardness. Often used in gears and shafts [13].

- Nitriding: Introduces nitrogen into the metal surface, forming hard nitrides. It occurs at lower temperatures than carburizing and produces minimal distortion [14].

- Induction Hardening: Uses electromagnetic induction to heat a metal part’s surface rapidly, followed by quenching. This creates a hardened outer layer while maintaining a ductile core [15].

4.2 Thermal Spraying

Thermal spraying involves projecting molten or semi-molten materials onto a surface to form a protective or functional coating. Common types include flame spraying, plasma spraying, and HVOF (High-Velocity Oxy-Fuel). It’s used for wear resistance, thermal barriers, and corrosion protection [16].

5. Coating and Painting

These processes apply a layer of material on the surface to provide protection, improve appearance, or deliver functional properties.

5.1 Painting

Painting applies liquid coatings that dry into solid films. It protects against corrosion and enhances aesthetics. Industrial paints can be solvent-based, water-based, or epoxy systems, depending on the application [17].

5.2 Powder Coating

Powder coating uses dry powdered paint applied electrostatically and then cured with heat. It results in a durable, uniform, and attractive finish. Powder coating is used for appliances, automotive parts, furniture, and more [18].

5.3 Vacuum Coating (PVD, CVD)

- PVD (Physical Vapor Deposition): Metal is vaporized in a vacuum and deposited onto the surface. It creates hard, decorative, and wear-resistant coatings used in tools, optics, and jewelry [19].

- CVD (Chemical Vapor Deposition): A chemical reaction occurs on the surface in a vacuum, forming a solid layer. CVD is used in semiconductors, aerospace, and cutting tools [20].

Conclusion

Surface treatment is a foundational part of manufacturing and product development. By choosing the right method—whether mechanical, chemical, electrochemical, thermal, or coating—you can dramatically improve the performance and lifespan of a material or component. Understanding the options available allows engineers and manufacturers to optimize for corrosion resistance, wear protection, aesthetics, or functional performance.

Whether you’re dealing with precision tools, architectural elements, or medical implants, there is a surface treatment technique to suit your needs. Carefully selecting the appropriate treatment ensures your product not only performs better but also stands up to the demands of its environment.

References

[1] Davis, J. R. (2001). Surface Engineering for Corrosion and Wear Resistance. ASM International.

[2] Totten, G. E. (2002). Handbook of Metallurgical Process Design. Marcel Dekker.

[3] Metal Finishing News. (2020). “Shot Peening: Principles and Applications.”

[4] Kalpakjian, S., & Schmid, S. R. (2013). Manufacturing Engineering and Technology. Pearson.

[5] ASM Handbook. (1994). Surface Engineering, Vol. 5.

[6] Benedict, G. F. (1987). Nontraditional Manufacturing Processes. CRC Press.

[7] ASTM A380/A380M – 17. “Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts.”

[8] Stainless Steel Information Center. (2018). “Passivation of Stainless Steel.”

[9] Electrochemical Society. (2016). “Chemical Conversion Coatings.”

[10] Matar, S. F. (2006). Electroplating: Fundamental Principles and Applications. Elsevier.

[11] MIL-A-8625F. “Anodic Coatings for Aluminum and Aluminum Alloys.”

[12] Donaldson, A. B. (2010). Electropolishing Technology and Applications. NACE International.

[13] ASM International. (1991). Heat Treating, Vol. 4.

[14] Rajan, T. V., Sharma, C. P., & Sharma, A. (2011). Heat Treatment: Principles and Techniques. PHI Learning.

[15] Handbook of Induction Heating. (2017). Taylor & Francis Group.

[16] Pawlowski, L. (2008). The Science and Engineering of Thermal Spray Coatings. Wiley.

[17] Paint and Coatings Industry. (2019). “Industrial Coating Solutions.”

[18] Powder Coating Institute. (2020). “Benefits of Powder Coating.”

[19] Mattox, D. M. (2010). Handbook of Physical Vapor Deposition (PVD) Processing. William Andrew Publishing.

[20] Hitchman, M. L., & Jensen, J. (1993). Chemical Vapor Deposition: Principles and Applications. Academic Press.