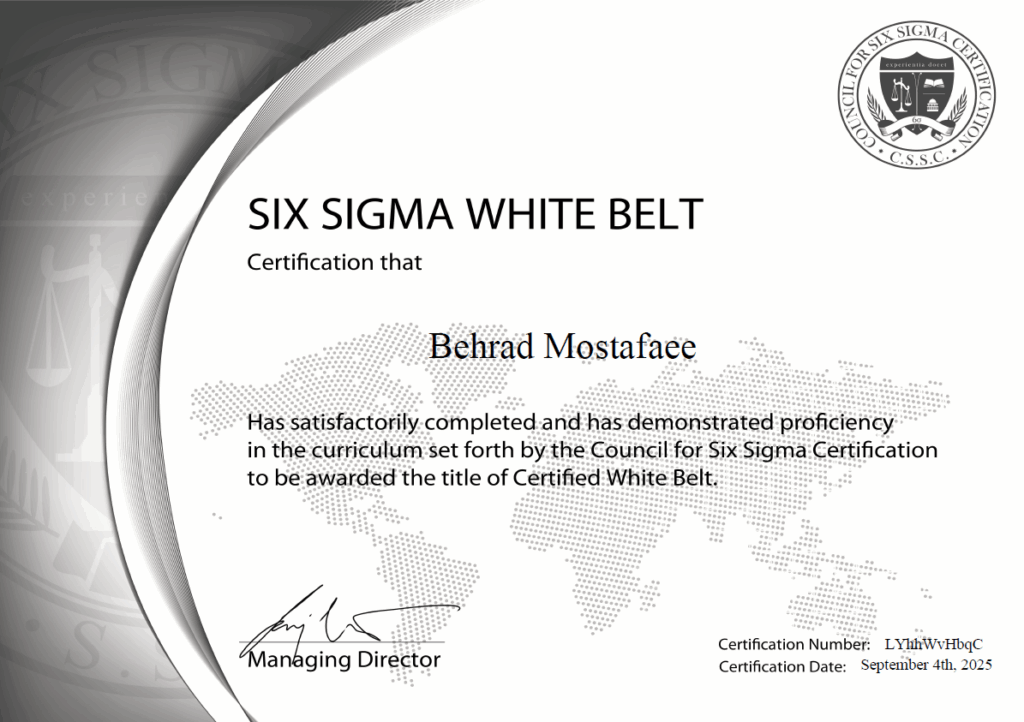

I officially completed my Six Sigma White Belt course and received my certification from The Council for Six Sigma Certification!

During this journey, I gained a solid foundation in process improvement and quality management, learning skills that are applicable in any industry. Here’s what I learned:

-

Process Mapping & Analysis: How to visualize and analyze workflows to identify inefficiencies and areas for improvement.

-

DMAIC & DMADV Frameworks: Understanding the core Six Sigma methodologies for improving existing processes (DMAIC) and designing new ones (DMADV).

-

Lean & TQM Principles: The basics of Lean thinking, eliminating waste, and Total Quality Management strategies for consistent quality.

-

Data-Driven Decision Making: Using metrics and statistical analysis to guide process improvements rather than relying on intuition.

-

Teamwork & Organizational Impact: The role of collaboration, ethics, and integrity in driving successful process improvements.

Completing the Six Sigma White Belt has given me a strong foundation to make processes more efficient, reduce defects, and deliver real results. I’m excited to continue advancing toward Green and Black Belt levels, and applying these skills to create meaningful impact in any organization.

For anyone curious about Six Sigma, you can check out The Council for Six Sigma Certification to learn more about certification paths and resources.