In my recent years of professional experience, I’ve encountered numerous companies struggling to manage their files effectively. Common challenges include how to properly store files on servers, establish clear naming conventions for designs, and implement coding systems to organize data efficiently. These seemingly small issues can quickly escalate, causing significant delays and management headaches. This is precisely where Product Data Management (PDM) and Product Lifecycle Management (PLM) systems become invaluable. Companies unfamiliar with these tools often face hidden costs—not only financially, but also in wasted time and operational inefficiencies. Improper file storage or errors in the latest design versions can lead to incorrect products, resulting in substantial costs and losses. In this post, I’ll explore how PDM and PLM can transform file management and streamline workflows in any organization.

What is Product Data Management (PDM)?

At its core, PDM is a system used to manage design data, particularly related to CAD files and other technical documentation. It’s a centralized digital vault where engineering teams store product-related data to ensure that everyone works from the same source of truth.

PDM is often tightly integrated with CAD tools and is essential for tracking revisions, controlling file access, and managing the release process of design documents.

Key Features of PDM:

-

Version Control: Keeps track of different versions of files so that teams avoid overwriting each other’s work.

-

Secure Access: Restricts file access based on roles or departments.

-

Change Management: Automates approval workflows for design changes.

-

Bill of Materials (BOM) Management: Ensures that BOMs are always consistent with the latest design.

Benefits of PDM in Engineering:

-

Reduces errors from working on outdated files.

-

Minimizes data loss and improves traceability.

-

Enhances collaboration within design teams.

-

Streamlines documentation and release processes.

Common PDM Software:

-

SolidWorks PDM

-

Autodesk Vault

-

PTC Windchill (PDM Module)

-

Siemens Teamcenter (PDM functionality)

PDM is typically a must-have for any engineering team working with CAD software, especially in regulated industries where traceability is vital.

What is Product Lifecycle Management (PLM)?

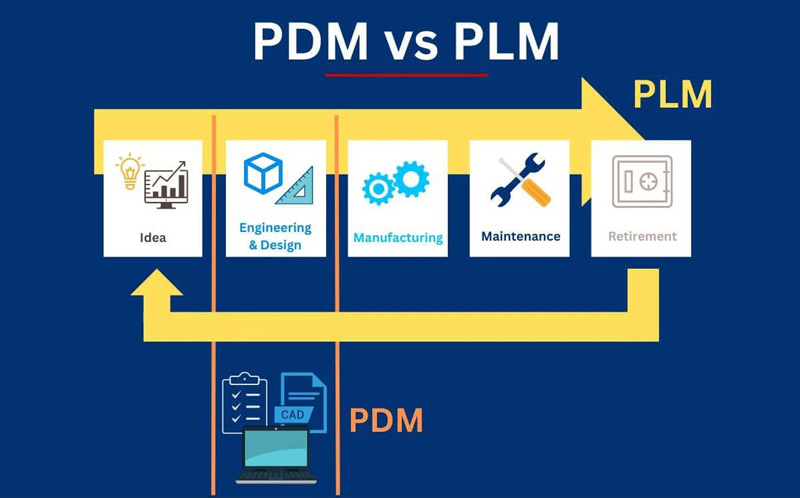

While PDM handles the technical data associated with product design, PLM is a broader solution that governs the entire lifecycle of a product. This includes everything from the initial concept and design, to manufacturing, service, and end-of-life disposal.

PLM acts as a central hub where all stakeholders—not just engineers, but also procurement, quality control, sales, and support—can collaborate. It unifies all product-related data, processes, and people across the enterprise.

Key Features of PLM:

-

Cross-Functional Collaboration: Integrates departments across the entire organization.

-

Product Development Process Management: Orchestrates workflows from concept to production.

-

Compliance and Regulatory Management: Tracks certifications, standards, and regulatory requirements.

-

Supply Chain Integration: Coordinates with suppliers and vendors.

-

Risk Management: Identifies and mitigates risks across the product lifecycle.

Benefits of PLM in Engineering and Beyond:

-

Reduces time-to-market by streamlining processes.

-

Improves quality and innovation through better collaboration.

-

Enhances compliance with industry regulations.

-

Supports continuous improvement and knowledge retention.

Common PLM Software:

-

Siemens Teamcenter

-

Dassault Systèmes ENOVIA

-

PTC Windchill

-

Autodesk Fusion Lifecycle

-

SAP PLM

PLM is more strategic and long-term in nature, often requiring cross-departmental buy-in and implementation support.

PDM vs. PLM: Key Differences

| Feature | PDM | PLM |

|---|---|---|

| Scope | Technical design files | Entire product lifecycle |

| Primary Users | Engineers, Designers | Cross-functional teams |

| Focus | File management, version control | Process and lifecycle management |

| Complexity | Simpler to implement | More complex and strategic |

| Integration | CAD-centric | Integrates with ERP, CRM, SCM systems |

| Data Coverage | Limited to design data | Broad, including cost, compliance, etc. |

The main takeaway: PDM is about files, PLM is about processes.

When Do You Need PDM?

If your engineering team frequently works on complex CAD assemblies, revises designs regularly, and collaborates on technical drawings, a PDM system is essential. PDM ensures data integrity, facilitates collaboration, and reduces the risk of errors or duplication.

Use Cases for PDM:

-

Small to medium design teams

-

High frequency of design revisions

-

Need for CAD file version control

-

Regulatory or certification needs (ISO, ASME, etc.)

PDM systems are often easier and quicker to implement compared to PLM and usually require less organizational change.

When Do You Need PLM?

As your company grows, so does the complexity of your products and processes. At this point, managing engineering data alone isn’t enough. You need to track product changes, manage suppliers, ensure compliance, and connect teams across the entire organization.

Use Cases for PLM:

-

Multi-departmental collaboration

-

Product compliance and documentation

-

Long development cycles with multiple stakeholders

-

Global manufacturing and supply chain

-

High-risk industries (aerospace, medical devices, automotive)

PLM is particularly useful when there’s a need for end-to-end visibility and control over the entire product development and lifecycle chain.

Real-World Engineering Example

Let’s take the example of an HVACR company designing a new thermal deburring machine:

-

In the early stages, PDM will help the engineering team manage CAD files, control revisions, and share designs internally.

-

As the project evolves, the company needs to collaborate with suppliers, track changes, manage quality documentation, and ensure compliance with the Pressure Equipment Directive (PED) and ATEX regulations. At this stage, PLM becomes essential.

This transition from PDM to PLM is a common path for growing companies as their product complexity and compliance needs expand.

Implementation Challenges

For PDM:

-

CAD integration issues if using multiple design tools

-

User adoption may take time

-

Limited scope: Does not manage non-technical data well

For PLM:

-

Complex implementation involving multiple departments

-

Higher cost and longer deployment time

-

Requires organizational change management

Choosing the right partner for implementation and ensuring staff are properly trained are critical success factors for both systems.

Conclusion: Which One Do You Need?

The answer depends on your organization’s current needs and future goals.

-

If your focus is on managing CAD files and design data, start with a PDM system.

-

If you aim to streamline processes across departments and manage the entire product journey, invest in a PLM platform.

-

For many companies, the journey starts with PDM and evolves into PLM as they scale.

In either case, implementing PDM or PLM is not just a software decision—it’s a strategic move that can improve efficiency, foster innovation, and maintain competitive advantage.

Final Thoughts

In engineering, precision and collaboration are non-negotiable. As products become more complex and teams more dispersed, systems like PDM and PLM are no longer optional—they are essential.

Whether you’re managing a small design team or overseeing an international product development operation, understanding the value and application of PDM and PLM can set your engineering projects up for success.

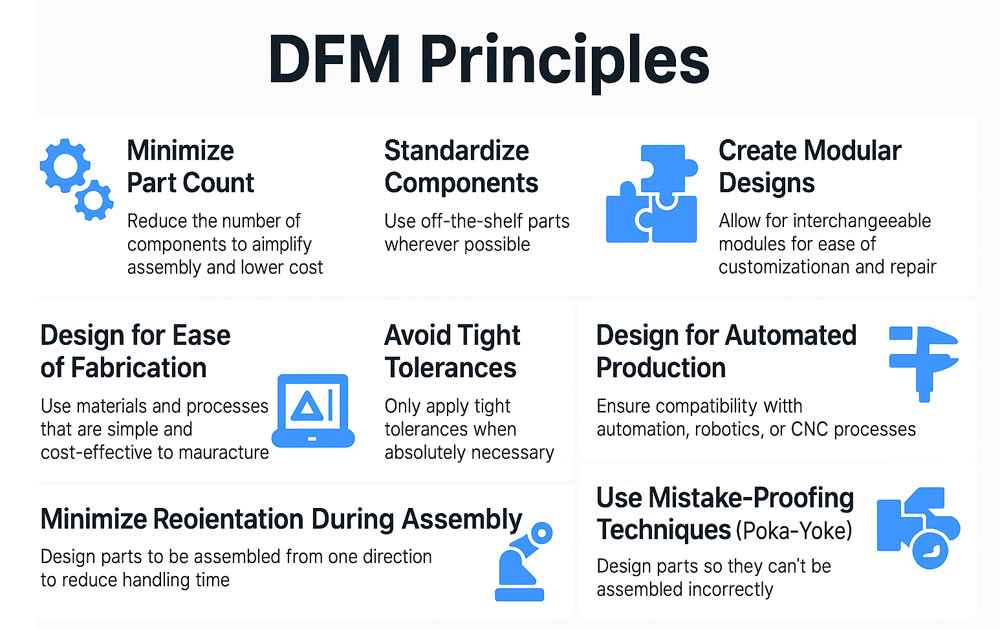

In the next post I will talk about the DFM (design for manufacturing), its principles and inplimintations in one of my designs.