Introduction to DFM: Bridging Design and Production

In the realm of product development, innovation alone is not enough. A brilliant design that cannot be manufactured efficiently is a missed opportunity. This is where Design for Manufacturing (DFM) becomes critical. DFM is a set of engineering practices aimed at designing products that are easy, cost-effective, and reliable to manufacture. By integrating manufacturing considerations early in the design phase, companies can significantly reduce production time, cost, and waste.

This comprehensive guide explores the principles, benefits, tools, and real-world applications of DFM, offering engineers and designers actionable insights to create production-friendly designs.

Why DFM Matters: The Case for Manufacturability

Design and manufacturing often exist in silos, resulting in late-stage changes, production delays, and cost overruns. According to a study by Boeing, over 70% of a product’s lifecycle cost is determined during the design phase. By incorporating DFM principles from the outset, companies can:

- Reduce design iterations and time to market

- Minimize production and material costs

- Enhance product quality and reliability

- Improve supply chain efficiency

In essence, DFM helps ensure that your product is not only innovative but also buildable.

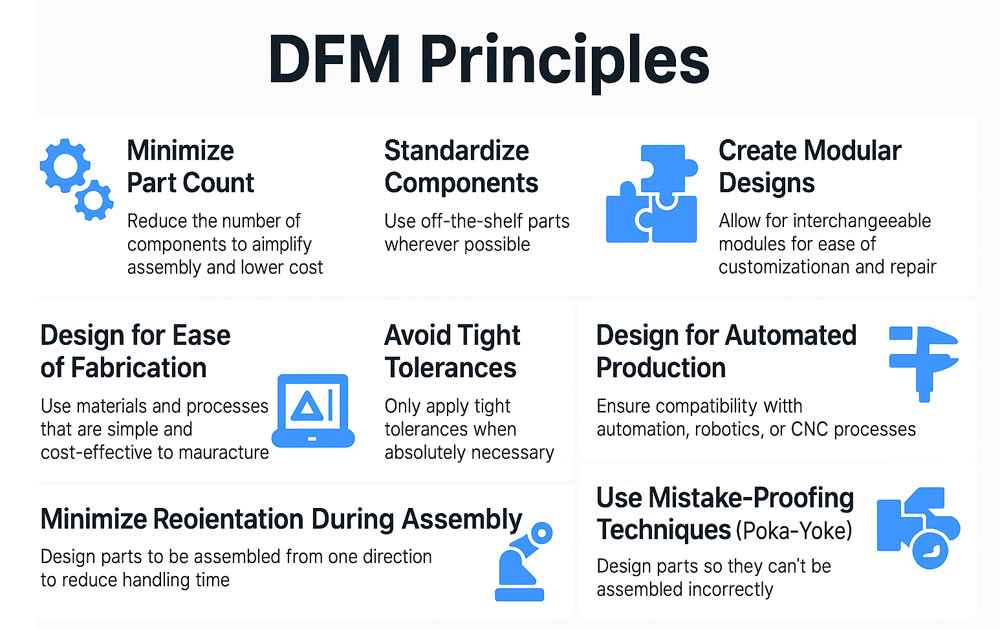

The 8 Core Principles of DFM

1. Simplify the Design

Objective: Reduce complexity without sacrificing functionality.

- Minimize the number of parts

- Avoid unnecessary features

- Combine components where feasible

Example: Apple is known for reducing internal components to streamline manufacturing and improve product longevity.

2. Optimize Assembly

Objective: Facilitate faster and more error-free assembly.

- Use self-locating and self-fastening features

- Design for ease of handling and orientation

- Minimize reorientation during assembly

3. Standardize Components

Objective: Use off-the-shelf parts to reduce cost and lead time.

- Adopt standard fasteners and connectors

- Use common material grades

- Avoid custom tooling whenever possible

4. Choose Suitable Materials

Objective: Match materials with manufacturing processes and performance needs.

- Consider machinability, moldability, and weldability

- Evaluate material costs and availability

- Assess environmental impact and sustainability

Material Selection Guide by Matmatch

5. Manage Tolerances Judiciously

Objective: Apply tolerances only where necessary.

- Avoid over-specifying dimensions

- Use Geometric Dimensioning & Tolerancing (GD&T)

- Consider process capability indices (Cp, Cpk)

6. Align Design with Manufacturing Processes

Objective: Leverage capabilities of specific production methods.

- Design for injection molding, casting, machining, etc.

- Avoid undercuts or features that require complex tooling

- Use process-specific design rules

Injection Molding Design Guide by Protolabs

7. Design for Environment

Objective: Consider environmental constraints and product lifecycle.

- Ensure thermal, chemical, and moisture resistance

- Plan for disassembly and recyclability

- Comply with regulations like RoHS and REACH

8. Prototype, Test & Iterate

Objective: Validate design and manufacturability before mass production.

- Use rapid prototyping (3D printing, CNC)

- Conduct stress and usability tests

- Implement design changes based on test results

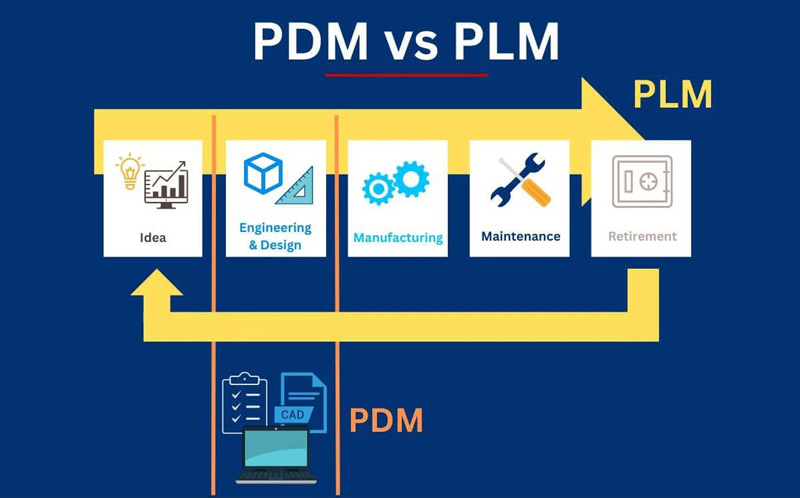

Tools and Techniques Supporting DFM

CAD and CAE Software

Modern design tools like SolidWorks, Autodesk Inventor, and PTC Creo offer built-in DFM analysis features. They can identify features that might cause manufacturing issues, such as thin walls or sharp internal corners.

Simulation and FEA

Finite Element Analysis (FEA) using tools like ANSYS or SimScale can help simulate stresses, thermal loads, and deformation during manufacturing, reducing the need for trial-and-error.

Tolerance Analysis Tools

Software like TolAnalyst and 3DCS Variation Analyst ensures that parts fit and function as intended within defined tolerances.

DFM Checklists

Using standardized DFM checklists for specific processes (sheet metal, injection molding, etc.) helps maintain consistency across design teams.

Real-World Applications of DFM

Automotive Industry

DFM is crucial in automotive design where high volumes demand repeatable and cost-effective manufacturing. Companies like Toyota implement DFM in every stage of vehicle development to streamline production.

Consumer Electronics

Smartphone manufacturers use DFM to minimize part count, optimize internal layouts, and ensure ease of assembly. For example, Samsung uses 3D CAD tools to simulate assembly processes.

Medical Devices

Due to strict regulations and the need for precision, DFM ensures that devices are manufacturable with minimal risk. Manufacturers follow DFM principles to meet FDA guidelines while maintaining cost-effectiveness.

Aerospace

With high safety standards, aerospace firms like Airbus integrate DFM to ensure parts are manufacturable, lightweight, and reliable under extreme conditions.

Benefits of Implementing DFM

| Benefit | Description |

|---|---|

| Cost Reduction | Lower material, labor, and overhead costs |

| Time Efficiency | Reduced time from design to production |

| Quality Improvement | Fewer defects and higher consistency |

| Sustainability | Reduced waste and environmental footprint |

| Customer Satisfaction | Faster delivery and more reliable products |

Common DFM Mistakes to Avoid

- Over-complicating the design with unnecessary features

- Ignoring manufacturing input during the design phase

- Over-tolerancing every dimension

- Selecting materials that are difficult or expensive to process

- Skipping prototyping and rushing into production

DFM in the Age of Industry 4.0

With the rise of digital manufacturing, DFM 4.0 integrates AI, machine learning, and digital twins to optimize product design and production in real-time. Tools like Siemens NX, Autodesk Fusion 360, and Dassault Systèmes’ DELMIA now provide intelligent DFM feedback to reduce iterations and boost efficiency.

Getting Started with DFM

Step-by-Step Implementation:

- Collaborate early with manufacturing, sourcing, and quality teams

- Use DFM checklists tailored to your product type

- Select tools and software that support manufacturability analysis

- Prototype and validate iteratively

- Document learnings to improve future designs

Education and Training

Invest in DFM training for your design and engineering teams. Online platforms like:

Conclusion: Design It Right the First Time

DFM is more than a checklist—it’s a mindset. It empowers design engineers to think like manufacturers and ensures that product concepts become reality smoothly and affordably. Whether you’re designing consumer goods, industrial machines, or cutting-edge electronics, incorporating DFM can significantly improve outcomes.

By embracing DFM early in your workflow, you not only save time and money but also build better, more sustainable, and user-focused products.

References:

- Boeing Cost Influence Study

- “Design for Manufacturing Principles” – Autodesk Redshift

- “DFM Guide” – Quality-One International

- Matmatch Materials Guide

- Protolabs Design Resources

- Coursera, MIT OCW and Udemy Courses

Pingback: Designing of a bus stop - Behrad Mostafaee